Spanish version LM-79-19 download:

ANSI/IES LM-79-19 Mediciones Fotométricas y Eléctricas de Productos de Iluminación de Estado Sólido (SSL)

This article tries to make a comparative evaluation between

ANSI/IES LM-79-19 Standard that has replaced

ANSI/IES LM-79-08 that deals with the methods approved by ANSI/IES regarding performance, requirements technicians of photometric and electrical parameters of

solid state lighting products (

SSL) from a perspective not necessarily specialized but with a user and academic vision regarding the technological devices involved.

In both cases it is also an approved method that describes the procedures that must be followed and the precautions that must be observed when making accurate reproducible measurements of the total, radiant or photonic luminous flux; electric power; system efficiency; distribution of light, radiant or photonic intensity and amounts of color and/or spectrum of solid state lighting (SSL) products for lighting purposes, under standard conditions.

It covers LED luminaires, OLED luminaires, integrated LED lamps, integrated OLED lamps, non-integrated LED lamps operated with a controller (driver) designated by the manufacturer's identification number or by a defined ANSI reference circuit, and LED light motors, all of which they will be called SSL products or

Device Under Test (

DUT). SSL products, excluding non-integrated LED lamps, are designed to connect directly to AC mains power or to a DC voltage power source for operation.

For millions of years, living beings on this planet have had the dialectical experience of light and dark with light, dark and gloom that established a lasting genetic and organic mark in our body that precisely regulates functions such as behavior, hormonal levels, sleep, body temperature and metabolism. In animated beings, the discovery of fire also generated important changes in their physiological, psychological and sociological development that transcends their behavior and survival. The invention of the electric light bulb, analogously to the formation of the sun for 4.5 billion years, has a decisive influence on the existential bases of the inhabitants of our planet.

On the other hand, the vertiginous technological development that occurs in these times in lighting technology that, among other things, provides for the widespread use of SSL products that could save approximately 348 TWh of electricity, a saving greater than US $ 30 billion already for the year 2027, they oblige to guarantee reliability in its use.

In that sense, the standards that guarantee this implementation must adapt quickly to this evolution. For this reason, the purposes of the American National Standard, which cover SSL or DUT products, generate new and better interpretations in the evaluation of the corresponding test results.

The ANSI/IES Standard

LM-79-08 is approved as an IES Agreement in December 2007 and as the National Standard the following year. It constitutes one of the first methods of testing SSL products and became a standard test method for the global measurement of this new technology. In Europe, the

CIE S 025 Standard was developed based on the experience of the LM-79 although it is broader and covers more measuring instruments in greater detail.

Document

ANSI/IES LM-79-19 is a revision of document

IES LM-79-2008. It makes changes to update the information and provides better guidance based on data collected from proficiency tests associated with laboratory accreditations and independent research. The updated requirements in this test method are intended to reduce the variation in measurement results between test laboratories, while minimizing the burden on those laboratories. The method is based on an absolute photometry that addresses the requirements for photometric and electrical measurement of SSL products.

Regarding its structure, the document has changed significantly to match the structure of the approved IES Test Procedure Committee document. Below, we present the additions made by Standard LM-79-19 in relation to LM-79-08:

1) Unlike the

LM-79-08, it emphasizes the accuracy of the measurements of all photometric parameters to be evaluated, incorporates and groups integrated LED lamps, integrated OLED lamps, non-integrated LED lamps operated with a controller designated by the Manufacturer identification number or by a defined ANSI reference circuit and LED light engines, all of which will be called SSL products or device under test (DUT).

2) It does not cover SSL products that require external heat sinks, nor does it cover components of SSL products, such as LED packages or LED arrays.

3) Additionally, it incorporates the following standards as references:

-

ANSI/IES RP-16-17: Nomenclature and Definitions for Lighting Engineering. New York: Illuminating Engineering Society; 2017. Free online viewing:

www.ies.org/standards/ansi-ies-rp-16/

-

IES LM-78-17: Method approved by IESA for the Measurement of the Total Luminous Flux of Lamps using an Integrating Sphere. New York: Illuminating Engineering Society; 2017

-

IES LM-75-01/R12: IES Guide for Measurement of Goniometers, Types and Photometric Coordinate Systems. New York: Illuminating Engineering Society; 2012

4) Add the definitions of Acceptance Interval (Interval of permissible measured quantity values), peak current crest factor (ratio of the absolute value of the maximum AC current divided by the RMS AC current) and Tolerance Interval allowed permissible values of a property.

5) Increase the tolerance range of ± 1.0 °C to ± 1.2 °C of the ambient temperature at which measurements are taken at 25 °C and the distance measured at a point of 1.0 m to no more than 1.5 m of the SSL product at the same height as the SSL product.

6) It adds in the goniometer air flow measurements that require movement of the device under test, a lower tolerance limit greater than 0.20 m/s in the instantaneous tangential velocity of any point in the DUT.

7) In Thermal Conditions for the assembly of SSL products add in support materials that have low thermal conductivity to polytetrafluoroethylene. It also points out that, although no specific requirements are established, in good laboratory practices they suggest that SSL products should not be subjected to excessive vibrations or shocks during stabilization, transport, assembly or testing. It also notes that, for goniometer measurements, scattered light must be suppressed in the test environment, through the appropriate use of low reflectance finishes on surfaces, shields and unfavorable areas

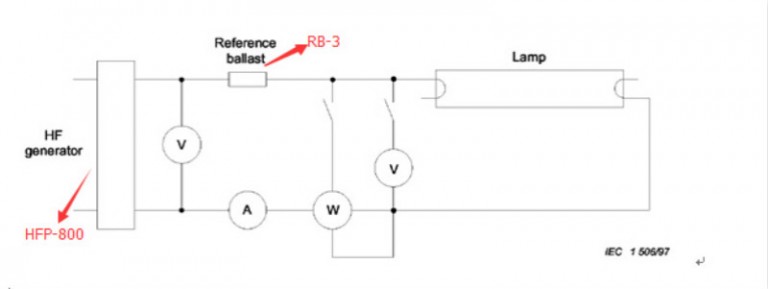

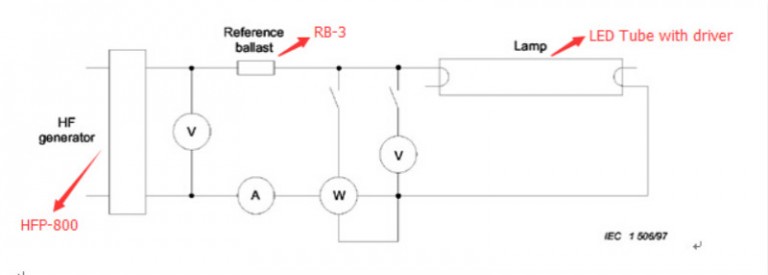

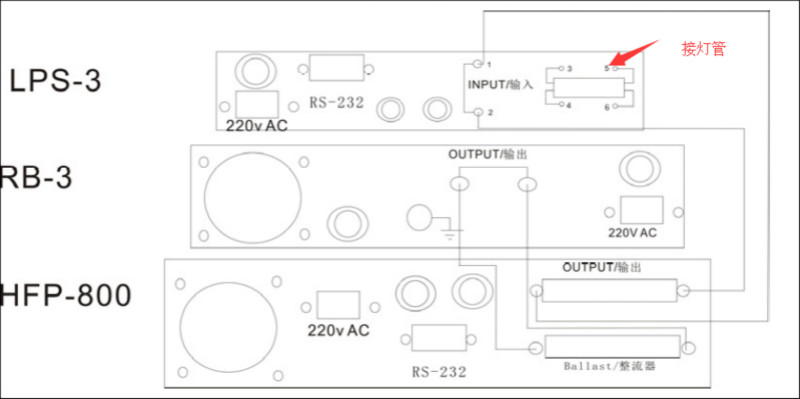

8) In addition the DC voltage regulation has been added in addition to the AC voltage regulation. Test circuit requirements are also added, to avoid the effects of voltage drops in cables or lampholders and requirements in the maximum resistance of the test circuit because a high resistance can alter the operation of SSL products. It is also noted that the capacitance of the test circuit, not including the power supply, must be less than 1.5 nanofarads (ɲF). Similarly, it is established that no reference circuit is necessary to test SSL products.

9) In relation to the Calibration of the electrical measuring instrument, it is established that all electrical measuring equipment must be calibrated and traceable to the International System of Units (SI) with values for the internal impedance of the voltage circuit, for accuracy of the alternating current meter, for the frequency range of the alternating current analyzer, for total harmonic distortion measurements, DC voltage measurement and DC current measurement.

10) Regarding the Electrical Configurations, it is indicated that the DUT will operate at the nominal AC RMS voltage or nominal DC current according to the SSL product specification for normal use. In addition, parameters are established for a variety of existing configurations, especially in the field of influence of American standards.

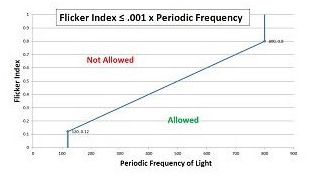

11) In Preparation of Tests, it establishes guidelines for the identification and management of DUTs. It is warned that, while SSL products will be tested without adaptations, if they are intended to be a verification standard or a device for laboratory comparison, SSL products must work for at least 1,000 hours before being put into service. It is also established that measures will be taken prior to the operation and stabilization of the DUT so that it operates long enough to achieve photometric and electrical stabilization and temperature equilibrium. It also establishes guidelines for the operating position and orientation of DUTs and optical and electrical waveforms.

12) In Measurements of the total luminous flux and integrated optics, the concept of DUTs is also incorporated, avoiding the use of incandescent or fluorescent lamps. The use of the integrating sphere (4π or 2π) with types of detectors is repeated to make measurements: V (λ) corrected photometer head (sphere-photometer) and spectroradiometer (sphere-spectroradiometer) and expands with the use of photometers and spectroradiometers describing their characteristics with advantages and disadvantages in each case and development of self-absorption correction concepts to minimize uncertainty. In general, unlike the

LM-79-08 Standard, the technical and mathematical concepts of the concepts are not developed and the practical and applicative aspect of the instruments and devices that integrate the corresponding measurement systems is emphasized.

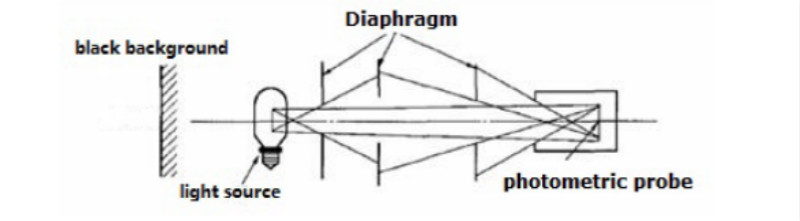

13) In relation to Luminous Intensityor Angular Distribution Measurements, develops a simplified and practical way the procedures and characteristics of the devices and components such as photometers, spectroradiometers, test distances and alignment of the goniometer.

14) In the same way, in the section on Uniformity and Chromaticity Measurements it establishes that SSL products may have a chromaticity variation with the emission angle and indicates that a measurement method was provided in Standard

LM-79-08 the integrated chromaticity and the spatial non-uniformity of the chromaticity when a goniospectroradiometer or a goniocolorimeter was not available; Thus, note that this method will not be used. It also defines the measurement characteristics for the angular resolution, the angular range, the angular uniformity of the color, the limits of the signals and the verifications.

15) Regarding Measurement of Uncertainty, understood as a quantitative measure of the quality of the measurement result, which allows the measurement results to be compared with other results, references, specifications or standards, it is stated that it is intended to limit the magnitude of the measurement uncertainty and that direct calculation of the measurement uncertainty is not required for an SSL product measurement given the tolerance intervals that have been provided throughout the Standard.

16) In Requirements reports, the concept of DUTs is incorporated and the pertinent data on the test conditions, the type of test equipment, the SSL products and the reference standards are simplified.

17) Some aspects that in the development of Standard

LM-79-19 have not been treated in statistical or mathematical detail, they have been able to be presented in the Annexes in a more orderly and didactic way. So that, information is supported on the Airflow Considerations for testing SSL products (Annex A), High Frequency Current and Circuit Capacitance Measurement (Annex B), Power Supply Resistance and Dependence of inductance (Annex C), Tolerance Intervals versus Acceptance Intervals (Annex D), Benefits of waveform measurements (Annex E) and Lower light intensity for chromatic uniformity (Annex F).

In general, we could set that due to the unique thermal and electrical characteristics of SSL products, standard test methods that use relative photometry cannot adequately measure the output of the luminous flux from LED light sources. The

LM-79 Standard solves this problem using absolute photometry. The revision of the same introduces the necessary changes due to the current technological development that, without substantially varying the basic concepts, facilitates the conditions of reliable evaluation of the measurement system and tests of photometric, optical and electrical devices involved.

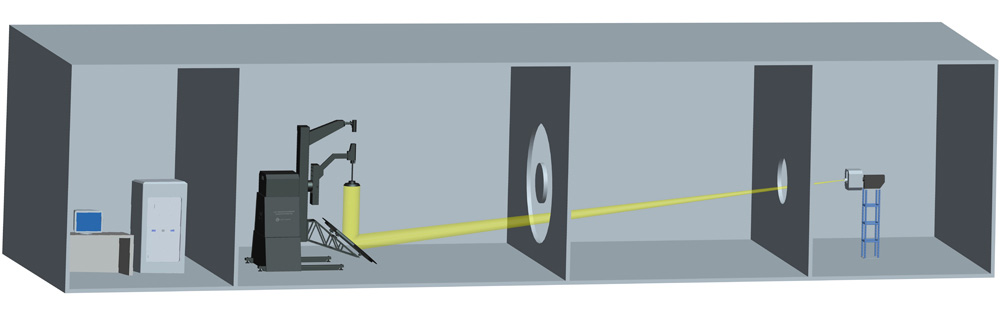

In fact, an adequate application of the parameters referred to in Standard

LM-79-19 to achieve reliable and accurate results as stipulated is the

LISUN model goniophotometer with motion detector model

LSG-5000SCCD Moving Detector Goniospectroradiometer that fully meets the requirements of goniophotometers type 4 indicated in this updated Standard (clause 9.3.1) and Standard

EN 13032-1 (clause 6.1.1.3) because it is an automatic test system with 3D light intensity distribution curves for light measurement from a variety of sources. In this way, information on Luminous Intensity, Luminous Intensity Distribution, Zonal Luminous Flux, Luminaire Efficiency, Luminance Distribution, Utilization Coefficient, Luminance Glare Limitation Curves, Maximum Distance to Height Ratio, Isoiluminancia Diagrams can be obtained, Luminaire curves vs. Illuminated area, Isocandela diagrams, Efficient Luminescence Angle, EEI (Energy Efficiency Index), UGR (Unified Glare Index) among others.

LSG-5000CCD Moving Detector Goniospectroradiometer

LSG-5000CCD Moving Detector Goniospectroradiometer

Likewise, for evaluations of SSL Products that identify the behavior of a single LED or an LED luminaire through its photometric, colorimetric and electrical parameters strictly following the standards prescribed by the updated

LM-79 Standard, systems of integrating spheres with radioradiometer spectrum high precision like the

LISUN LPCE-2 High Precision Spectroradiomet Integrating Sphere System model that is applied with a CCD spectroradiometer and worked with an integrating sphere model with a cyclic test base with more accurate results. In this way,

colorimetric measurements can be made (chromaticity coordinates, CCT correlated color temperature consistency, color ratio, peak wavelength, average broadband, dominant wavelength, color purity, CRI color reproduction index , CQS, TM-30, Spectrum test),

photometric (luminous flux, luminous efficiency, radiant power, EEI energy efficiency index, energy efficiency class, pupillary flow, pupillary flow efficiency, pupillary factor, cirtopic flow),

electrical (voltage, current, power, power factor - options: VF, IF, VR, IR) as well as

optical maintenance tests with SSL products in accordance with the

LM-80 standard (luminous flux versus time, CCT versus time, CRI versus time , power versus time, power factor versus time, electric current versus time and flow efficiency versus time).

Although Standard

LM-79 specifies the parameters of individual products and the test data obtained cannot be used to evaluate similar products and perform lighting calculations.

LM-79and this new approved version does not specify any sampling size. If the quantity of samples that can be subjected to a test is not specified, this could generate some vulnerability of the lower quality products.

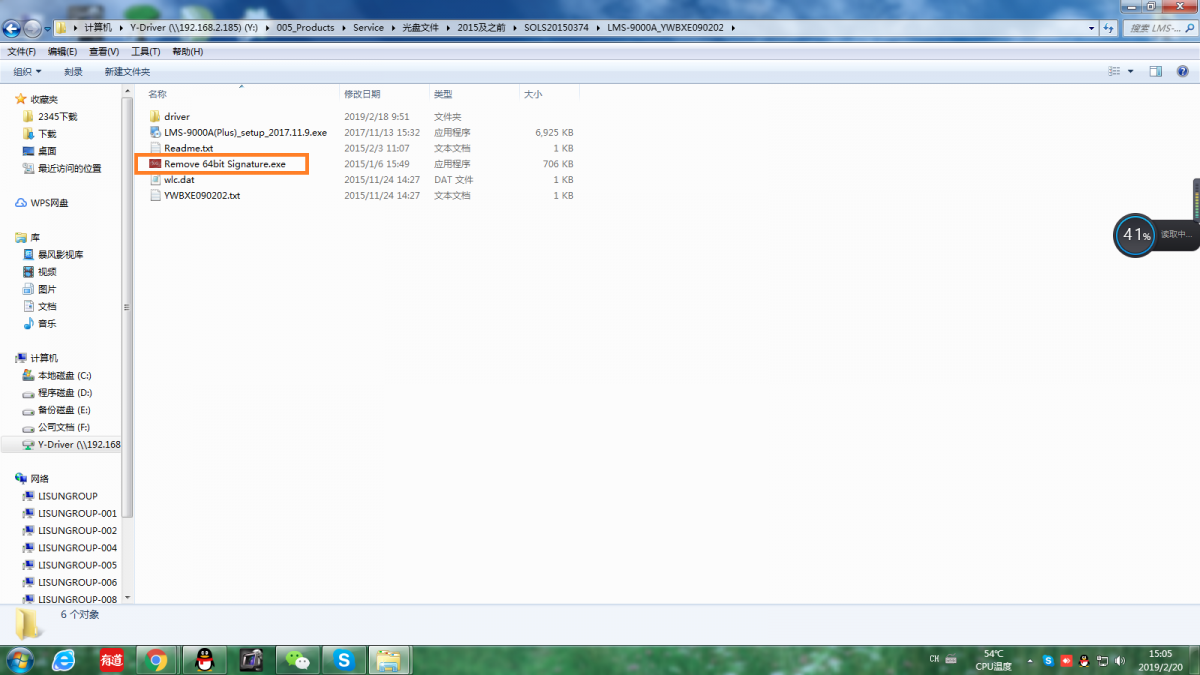

LPCE-2(LMS 9000) Spectrophotometer & Integrating Sphere Test System

LPCE-2(LMS 9000) Spectrophotometer & Integrating Sphere Test System

References:

- ANSI/IES LM-79-08 y LM-79-08, Método aprobado: Mediciones Fotométricas y Eléctricas de Productos de Iluminación de Estado Sólido (SSL)

- UNE-EN 13032-4 Norma Española: Luz y Alumbrado, Medición y Presentación de Datos Fotométricos de Lámparas y Luminarias. Parte 4: Lámparas LED, módulos y luminarias. Octubre 2016.

- Cie 17.4, 1987 International Lighting Vocabulary.

- Protzman / k. Houser. LEDs for General Illumination: State of the Science. LEUKOS, 121-142, 2006.

- Moon. Scientific Basis of Illumination Engineering. Electrical Engineering Texts, 1966.

- Gershum. The Light Field, 51-151, 1936.

- LISUN - Solutions for testing LED luminaires and electronic drivers. Electric current versus time and flow efficiency versus time).

- LISUN - Test system with integrating sphere & spectrophotometer: LPCE-2

Lisun Instruments Limited was found by LISUN GROUP in 2003. LISUN quality system has been strictly certified by ISO9001:2015. As a CIE Membership, LISUN products are designed based on CIE, IEC and other international or national standards. All products passed CE certificate and authenticated by the third party lab.

Our main products are

Goniophotometer,

Spectroradiometer,

Integrating Sphere,

LED Test Instruments,

CFL Test Instruments,

Photometer and Colorimeter,

EMC & EMI Testing,

Surge Generator,

Electrical Safety Testing,

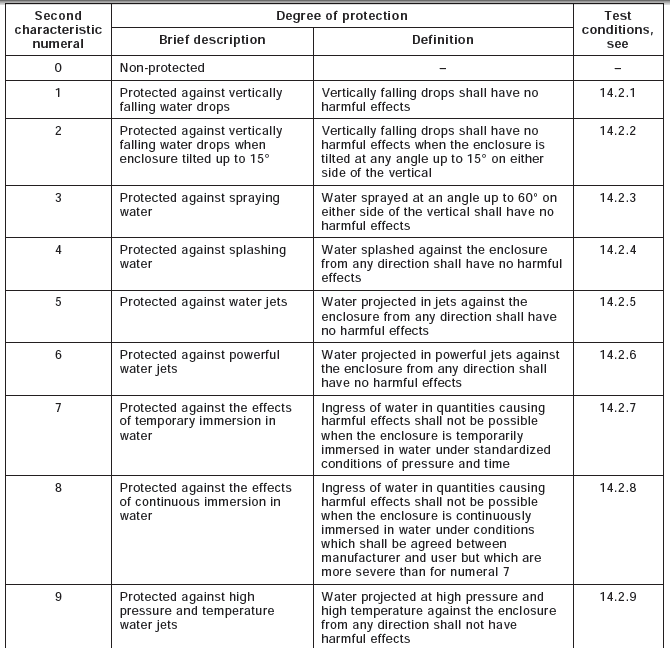

Environmental Test Chamber, IP

Waterproof Test Equipment,

Dustproof Test Chamber,

High and Low temperature Humidity Chamber,

Plug and Switch Testing,

AC and DC Power Supply.

Please feel free to contact us if you need any support.

Tech Dep:

Service@Lisungroup.com, Cell/WhatsApp: +8615317907381

Sales Dep:

Sales@Lisungroup.com, Cell/WhatsApp: +8618917996096

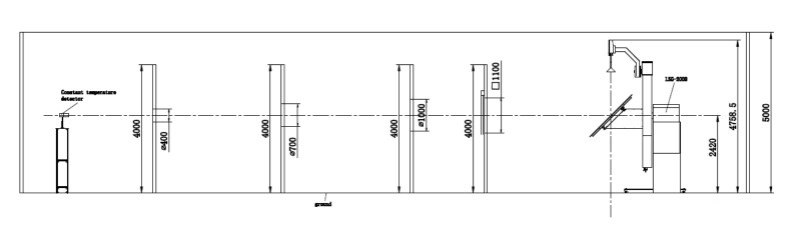

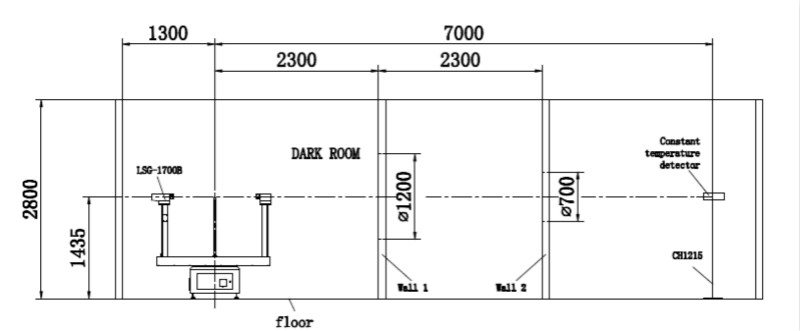

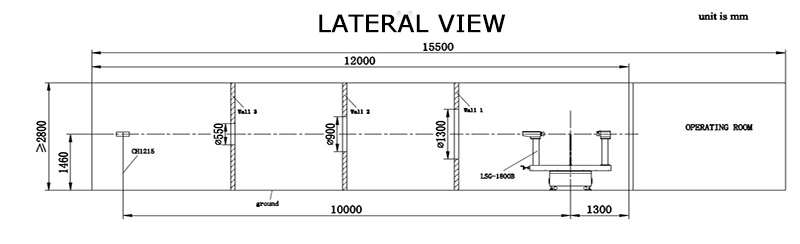

LSG-1700B High Precision Rotation Luminaire Goniophotometer

LSG-1700B High Precision Rotation Luminaire Goniophotometer

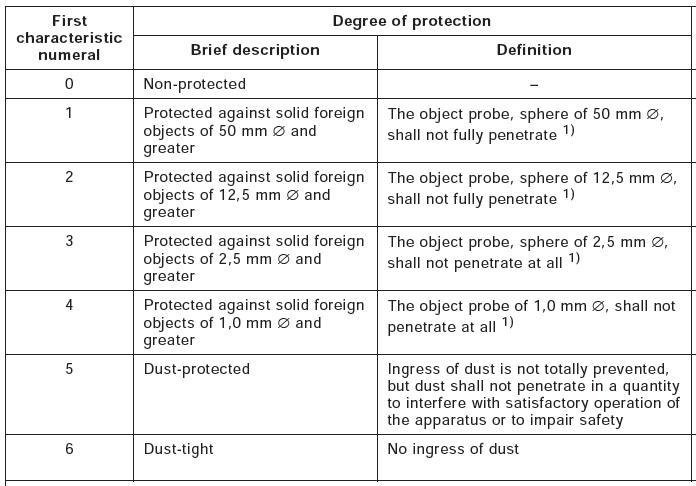

SC 015_Dustproof Testing Machine

SC 015_Dustproof Testing Machine